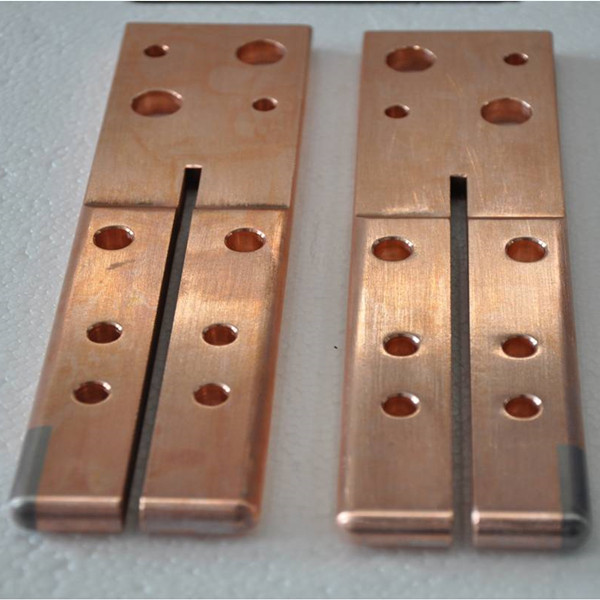

1. Better heat resistant;

2. Better ablate-resistant;

3. High intensity.

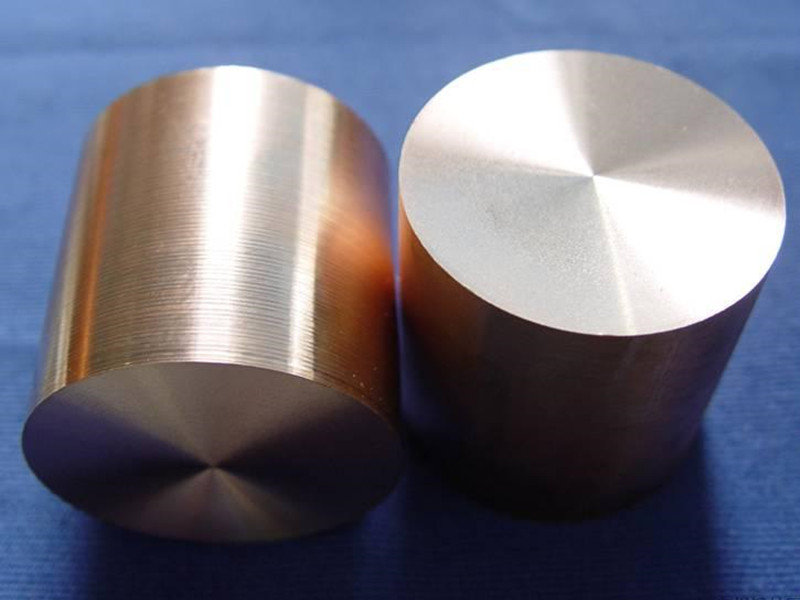

Tungsten copper (Cu-W) alloy is the composite of tungsten and copper which own he excellent performance of tungsten and copper. It is used widely in such industries as engine, electric power, electron, metallurgy, spaceflight and aviation. 1) Arcing contacts and vacuum contacts in high and medium voltage breakers or vacuum interrupters 2) Electrodes in electric spark erosion cutting machines 3) Heat sinks as passive cooling elements of electronic devices 4) Electrodes for Resistance Welding.

| Code No. | Chemical Composition % | Mechanical properties | ||||||

| CU | Impurity≤ | W | Density (g/cm3 ) ≥ | Hardness HB ≥ | RES (μΩ·cm) ≤ | Conductivity IACS/ % ≥ | TRS/ Mpa ≥ | |

| CuW(50) | 50±2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | |

| CuW(55) | 45±2.0 | 0.5 | Balance | 12.30 | 125 | 3.5 | 49 | |

| CuW(60) | 40±2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | |

| CuW(65) | 35±2.0 | 0.5 | Balance | 13.30 | 155 | 3.9 | 44 | |

| CuW(70) | 30±2.0 | 0.5 | Balance | 13.80 | 175 | 4.1 | 42 | 790 |

| CuW(75) | 25±2.0 | 0.5 | Balance | 14.50 | 195 | 4.5 | 38 | 885 |

| CuW(80) | 20±2.0 | 0.5 | Balance | 15.15 | 220 | 5.0 | 34 | 980 |

| CuW(85) | 15±2.0 | 0.5 | Balance | 15.90 | 240 | 5.7 | 30 | 1080 |

| CuW(90) | 10±2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

4. High density; 5. Excellent thermal and electrical conductivity; 6. Easy to be machined.